The ICUMSA 45 standard serves as a vital guideline for defining the purity of white sugar. This international standard establishes precise specifications that producers must adhere to, ensuring a consistent and reliable substance. ICUMSA 45 covers a wide range of factors, such as color, humidity, and the presence of contaminants. By meticulously measuring these characteristics, ICUMSA 45 guarantees consumer confidence in the quality and consistency of white sugar worldwide.

Delving into ICUMSA 45 Standards for Refined Sugar

The International Commission for Uniform Methods of Sugar Analysis (ICUMSA) sets the globally recognized benchmarks for sugar quality and analysis. ICUMSA 45, specifically, focuses on the attributes of refined sugar, ensuring uniformity and consistency in its worldwide market. This standards cover a variety of aspects, including color, moisture content, impurities, and melting point. Adherence to ICUMSA 45 promotes that refined sugar products meet the essential quality requirements for read more various applications, from food manufacturing to pharmaceutical use.

Additionally, understanding ICUMSA 45 enables manufacturers and consumers with a common platform for sugar quality assessment, facilitating trust in the supply chain.

Characteristics and Applications of ICUMSA 45 Sugar

ICUMSA 45 sugar refines a distinct type of sucrose renowned for its hue. It is characterized by pale golden hues, setting it apart from brighter varieties. This unique trait stems from the extent of processing involved in its creation. ICUMSA 45 sugar finds multiple applications in the food and beverage industry. It is often utilized as a fundamental element in bakery products, contributing to their sensory experience.

Furthermore, ICUMSA 45 sugar acts a crucial role in enhancing the consistency of certain food products. Its ability to dissolve readily into mixtures makes it a valuable asset for manufacturers seeking to achieve specific textural qualities.

Measuring Purity: The Role of ICUMSA 45 Testing

In the intricate world of sugar refining, verifying purity is paramount. This meticulous process involves a standardized testing protocol known as ICUMSA 45. This methodology is universally recognized by industry specialists as the gold standard for quantifying non-sugar impurities within sugar samples. ICUMSA 45 employs a specific set of procedures that encompass dissolving a sample in the suitable solvent and then measuring its absorbance at defined wavelengths. The resulting data is carefully analyzed to determine the level of impurities present, providing valuable insights into the sugar's quality and suitability for various applications.

- Consistently monitoring purity through ICUMSA 45 testing allows manufacturers to

- maintain consistent product quality.

- Consequently, this contributes to customer confidence.

The ICUMSA 45 Standard: Ensuring Superior White Sugar Quality

For manufacturers and consumers alike, ensuring the excellence of white sugar is paramount. This is where ICUMSA 45 steps in, serving as a global benchmark for refined white sugar. Established by the International Commission for Uniform Methods of Sugar Analysis (ICUMSA), this standard outlines stringent criteria for various aspects of sugar production and processing. Adherence to ICUMSA 45 guarantees that a product meets high standards, ensuring color, purity, and other critical properties are within acceptable ranges.

The benefits of ICUMSA 45 certification are multifaceted. It provides confidence to consumers that the sugar they purchase meets a certain level of quality, improving consumer faith. For manufacturers, it signifies their commitment to producing premium products and can provide a sales advantage. ICUMSA 45 ultimately promotes fair trade practices within the sugar industry by providing a universal language for evaluating and comparing sugar quality.

The Impact of ICUMSA 45 on Sugar Industry Regulations

The implementation of ICUMSA 45 has significantly shaped the regulatory landscape for the global sugar industry. This in-depth set of standards, focused on cane syrup, provides a unified framework for measurement and quality. The adoption of ICUMSA 45 has streamlined exchange by ensuring that sugar goods meet consistent criteria throughout the supply chain.

Furthermore, ICUMSA 45 has prompted industry-wide collaboration and knowledge sharing. It has also strengthened the accuracy of sugar testing methods, leading to greater transparency within the market. As a result, ICUMSA 45 has emerged as as a essential element in overseeing the sugar industry and ensuring its sustainability.

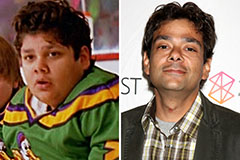

Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Dolly Parton Then & Now!

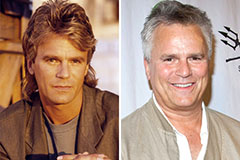

Dolly Parton Then & Now! Richard Dean Anderson Then & Now!

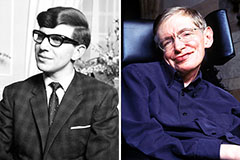

Richard Dean Anderson Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!